10/30/24

BrainDrip’s Health and Risk Monitoring System: Asset Reliability, All the Time

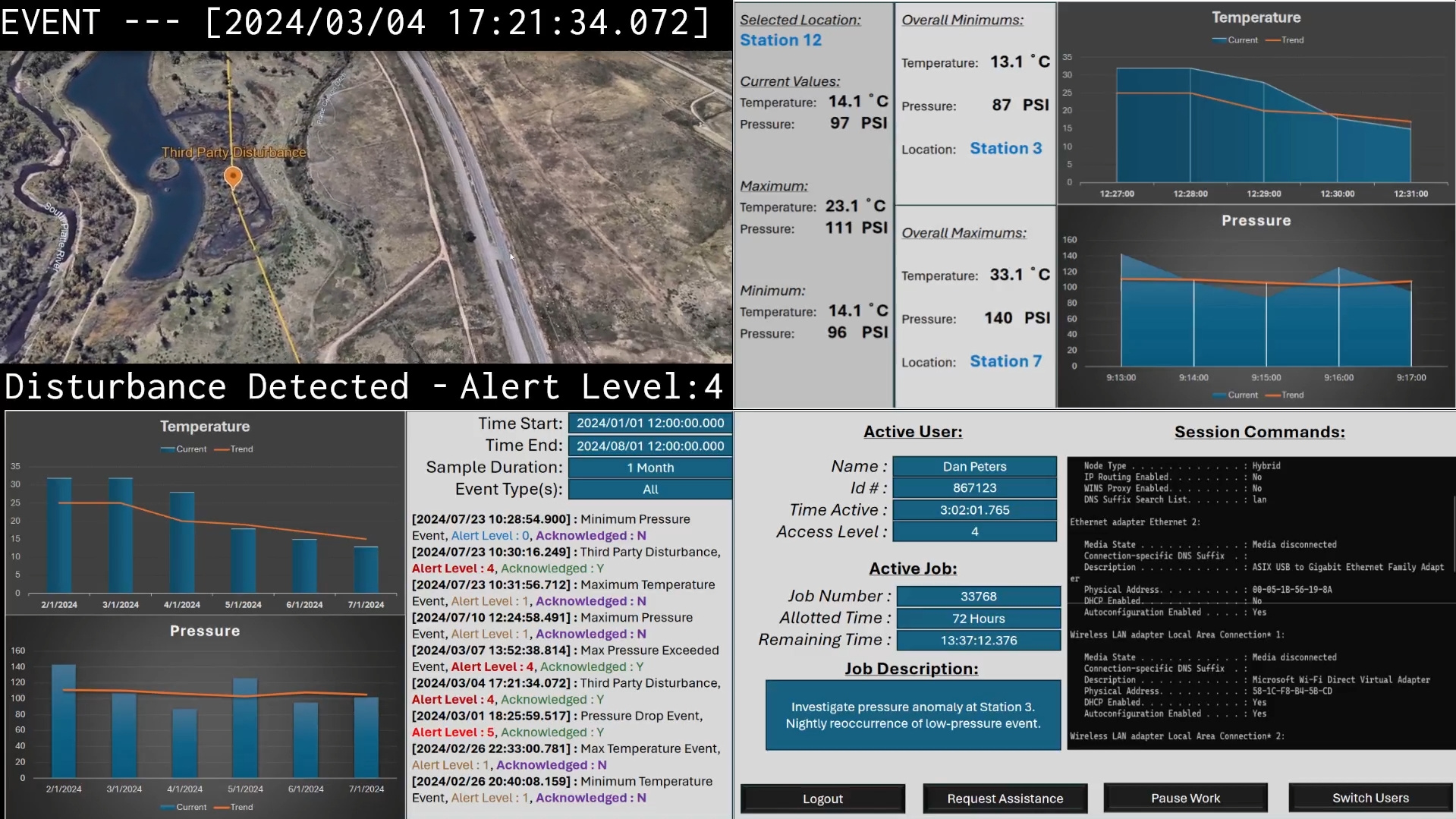

One of BrainDrip's HRMS interactive display interfaces, providing configurable event notification and real-time and historical summary results.)

A Changing Buried Asset Management Landscape

Due to the critical infrastructure that pipelines provide to modern society, system reliability is of critical importance regardless of the pipeline materials and construction methods used. A broad range of pipeline inspection and health monitoring solutions exist, including direct inspection using cameras, smart In-line Inspection tools (PIGS), and dynamic models that aim to capture upset pipeline conditions with traditional instrumentation. There are significant and continual advancements of technologies and methods in the asset management space. Many of these inspection solutions are developed to assess the failure modes in metallic piping systems, often providing a periodic snapshot in time of the asset’s health. As compliance and regulations continue to become more stringent, will traditional methods for inspection be able to adapt and innovate quick enough to keep up?

Regulatory Requirements on Top of Regulatory Requirements

Pipeline health and risk monitoring varies significantly in its importance, requirements, and objectives. One trend that remains persistent is the increasing stringency of requirements for leak detection, asset damage, and tracking emissions for energy assets. As these requirements become more stringent, there are opportunities for innovation with a wide range of approaches currently being pursued.

BrainDrip’s Health and Risk Monitoring Solution (HRMS)

The HRMS developed by BrainDrip leverages a combination of advanced sensors, available instrumentation, and Machine Learning/A.I. based software platforms to create a comprehensive asset management solution. The HRMS is compatible with any composite liner system and is suitable for traditional buried asset types where health and risk monitoring are important (E.g., cast iron, concrete, etc.). In addition, the HRMS can be deployed with other polymer-based liner products, traditional steel pipes, and even for tubular storage assets such as Type IV stationary ground storage.

Distributed fiber optic sensing methods and associated algorithms form the core of continuous monitoring within the HRMS, and provide unparalleled insights into the system and surrounding environment. Distributed fiber optic sensors probe the fundamental vibrations in the system and environment, temperature conditions, and monitor extremely small changes to the system at the speed of light. As these fundamental conditions change, the HRMS interprets the changes and makes determinations of when the changes warrant action. Where fiber optic installation is needed in an existing asset such as a steel pipe, BrainDrip’s complimentary robotic Fiber Optic Deployment Tool (FODT) can be used to instrument the system for health and risk monitoring. For assets that require only a portion of the full HRMS capabilities, individualized solutions can be provided as BrainDrip provides customized solutions for unique and challenging applications.

Addressing Diverse Market Needs

BrainDrip’s HRMS has been designed for compatibility across the diverse buried pipeline markets that exist today. HRMS is critical for flammable gas pipeline systems where a disruption of service has large consequences for customers, gas leaks pose an environmental emissions threat, and the risk of a combustion event and catastrophic failure becomes high. In addition, for assets going through a fuel transition, such as the progressive decarbonization of natural gas through gas blending of hydrogen, the HRMS must be designed for compatibility and the introduction of any new potential failure modes. Similarly, for water or waste water transmission systems, disruption of service can have large consequences for the community, and system failures can create significant localized environmental damage and repair costs. Finally, applications such as stormwater sewers and even liquid petroleum product pipelines have unique considerations, risks, and consequences that BrainDrip’s HRMS is designed to mitigate.

Innovative Liner Products Enable Innovative Monitoring Solutions

While offering unique solutions to the market, composite liner systems materials construction and properties significantly differ from traditional metallic pipeline assets. By designing the continuous health and risk monitoring systems to capture the risks and potential failure modes of the pipeline product, reliability can be maximized while also minimizing or eliminating the need for costly periodic inspection methods. This strategy applied to BrainDrip’s innovative composite liner products (Innervated Tubular Composite, ITC) forms the basis for BrainDrip’s HRMS. These material differences translate to different potential failure modes, although many of the threats to the system remain the same. Due to the unique construction of composite liner systems, advanced sensor systems can be integrated into the product and provide superior health and risk monitoring performance. BrainDrip’s HRMS accomplishes this by integrating acoustic, strain, and temperature based distributed fiber optic sensing into its pipeline liner assembly. Third-party threats such as encroachment and digging in proximity to the asset are identified through acoustic sensing, providing preventative measures against potential system damage. Ground movement-based threats to the system such as landslides are identified in real-time, accompanied by continuous product damage assessment and event localization. With continuous monitoring of the composite reinforcement, early indicators of accelerated degradation or failure provide an opportunity for mitigation, significantly reducing the risk of a catastrophic event. Finally, leaks and other potential failures in containment are rapidly identified and pinpointed within the system.

Confidence Where You Need It, When You Need It

When combining the HRMS with BrainDrip’s mobile-onsite liner production method and quality assurance/quality control practices, a comprehensive strategy is formed to ensure that the product meets specifications and performs throughout its expected lifetime. In addition to preventative threat avoidance, event detection, and consequence mitigation, the HRMS also provides system performance metrics such as current operating pressure and temperature statistics and historical summaries. Through adaptability in the installation process, monitoring resolution can be tailored to the application, providing high resolution monitoring in sensitive environmental areas, waterways and crossing points, higher risk location classes, and other high consequence areas. HRMS events are localized on the scale of feet to meters, providing precise dispatch for further assessment when necessary. By integrating distributed fiber optic sensors into the product, direct assessment of product risk is obtained, rather than by proxy such as buried acoustic systems installed adjacent to the asset. Finally, by integrating the embedded distributed fiber optic systems with select traditional sensors and machine learning algorithms, events and out-of-bounds operating conditions are identified with a high degree of precision and accuracy.

Intuitive and Comprehensive Results

Events triggered through BrainDrip’s HRMS system provide critical information to the asset operator in real-time so that decisions can be made quickly. For instance, a third-party threat such as heavy equipment operating in area is identified and categorized, providing insight to the type of threat. Additional information such as the initial time that the equipment came into proximity of the asset, periodic updates in event time duration, and the geospatial location range of interest are included in the notification and can be customized through the user interface. Similarly, if a ground movement event such as a landslide were to occur, the anomaly is categorized, providing insights to the type of threat. Additional information such as the initial time of the landslide, updates in the duration of the land movement, and geospatial location range of interest are included. In addition, if this type of event were to damage the asset, supplemental notifications are provided that could include temperature change warnings, reinforcement integrity notifications, overpressure notifications, and/or leak notifications. With a well designed and safe system, events become infrequent and the HRMS continues to deliver additional value through high-resolution real-time and historical performance data. Information such as pipeline operating pressure, temperature, and even long-term multi-year composite reinforcement performance tracking are provided

BrainDrip – Your Pipeline To Safe and Reliable Assets

Whether you are seeking to retrofit/rehabilitate an outdated buried pipeline asset, seeking to future-proof pipeline assets for a changing market, install a greenfield pipeline asset, or add robust health and risk monitoring to an existing asset, BrainDrip provides a suite of innovative and customizable solutions. Our HRMS provides superior performance to ensure that your buried asset remains in peak operating condition throughout its expected lifetime and minimizes or eliminates costly inspection practices and potential downtime. To learn more about BrainDrip’s HRMS, our composite pipeline liner systems, or even our large-scale composite energy storage products, please visit us at https://braindriptech.com