Transitioning the world’s pipeline and storage infrastructure to meet the needs of future high-volume energy markets.

Materials • Systematization • Automation • Implementation

Who We Are

Welcome to BrainDrip and thank you for your interest. At BrainDrip LLC, innovation drives everything we do. As an employee-owned innovation hub, we specialize in designing, manufacturing, and deploying advanced composite pipeline and energy storage solutions. Our mission is to revolutionize the industry with cutting-edge products and field services that solve today’s challenges while preparing for tomorrow’s energy needs.

BrainDrip Announces Launch of their BD Composites Brand to Advance Pipe & Manufacturing Technology

BrainDrip has built a strong reputation as a pioneering developer and incubator of ‘Patently True’ technologies—novel, disruptive solutions that span multiple industries. From initial concept, engineering, prototyping and patent development to field implementation, BrainDrip delivers innovations that redefine industry standards.

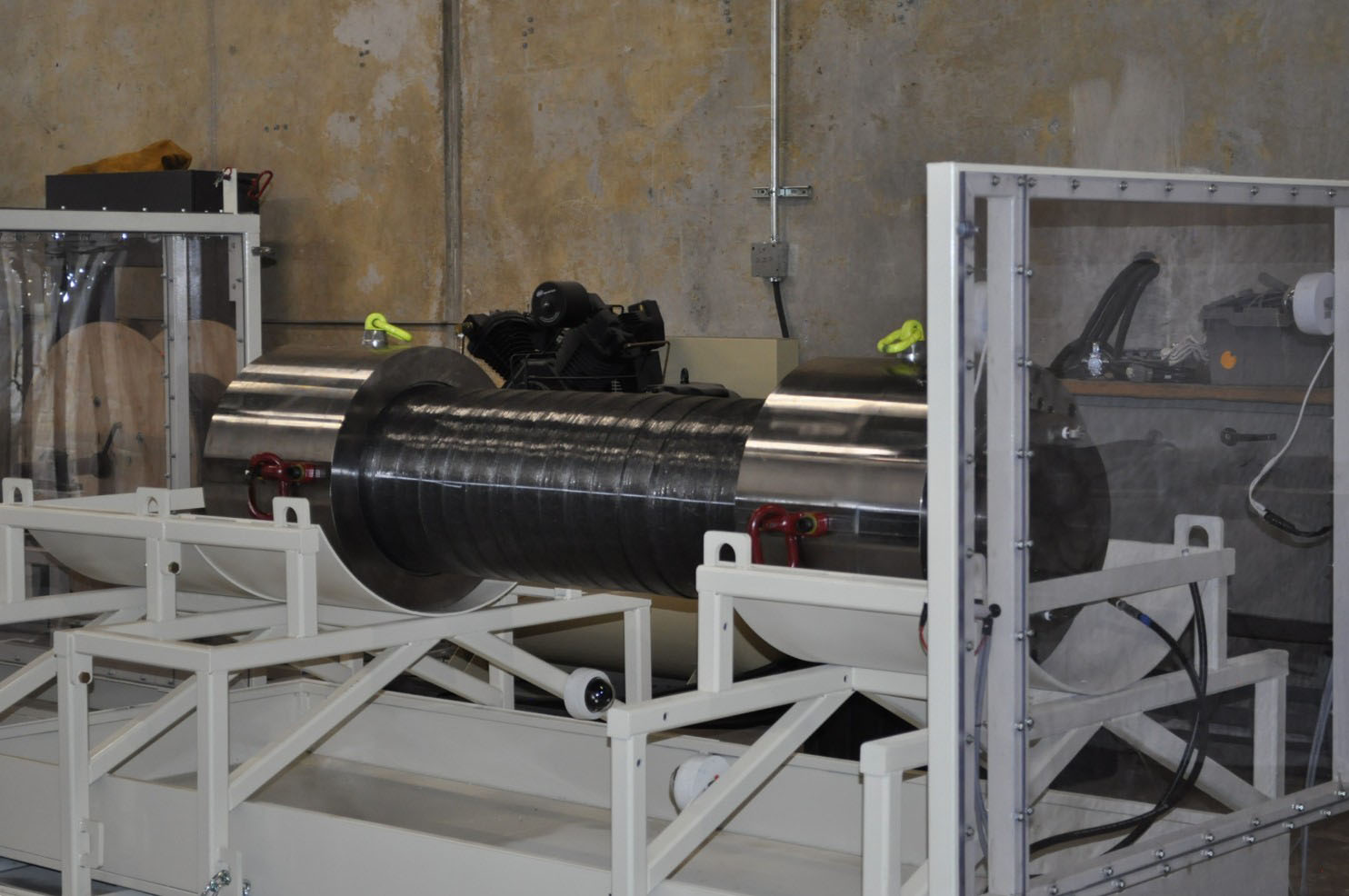

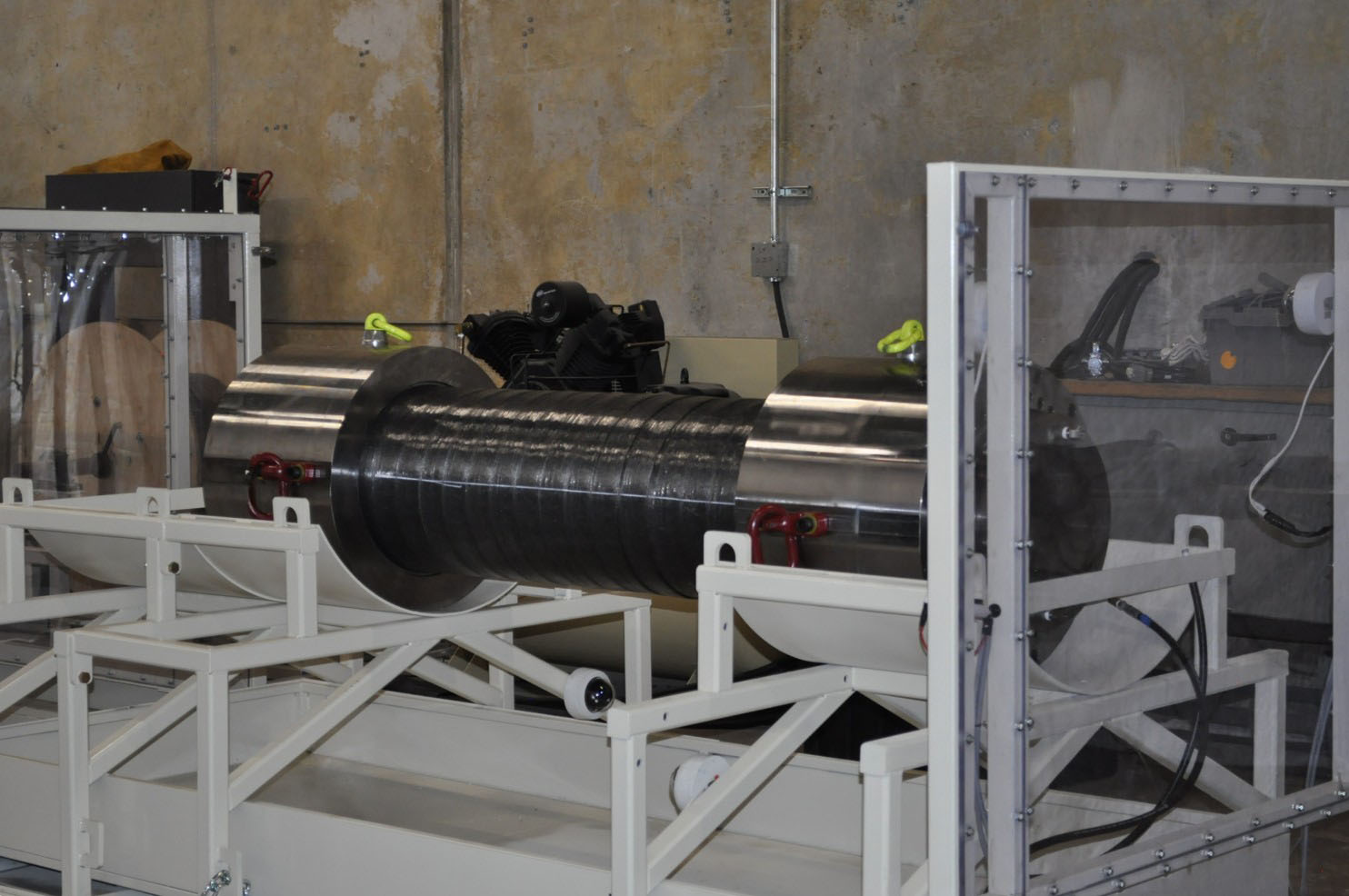

Since 2018, BrainDrip has been focused on the development, rigorous testing, and recent field deployment of a groundbreaking mobile manufacturing system. This platform produces our automated composite pipe, offering unprecedented efficiency, scalability, and quality for pipeline construction and maintenance. As with all BrainDrip technologies, once a solution reaches a defined level of maturity, it is transitioned into a dedicated brand to support focused growth and commercial scalability. We are proud to announce that this transformative technology has found its new brand: BD Composites.

BD Composites will carry forward the branding mission for BrainDrip’s deployment of composite pipeline and energy storage solutions and their patented field manufacturing systems on a global scale, advancing the next generation of pipeline infrastructure.

A History of Collaboration

By fostering creativity and collaboration, we empower our team to push boundaries, pool expertise, and create groundbreaking intellectual property. This culture of exploration has positioned us at the forefront of energy transmission and storage innovation, making BrainDrip the partner of choice for utilities, energy companies, and forward-thinking infrastructure investors.

At BrainDrip, we don’t just deliver products—we partner with our customers throughout the entire project lifecycle. From concept development and feasibility/FEED studies to on-site manufacturing, commissioning, and ongoing operations supported by our integrated health monitoring, we ensure every project’s success. By combining cutting-edge technology with comprehensive support, we enable our customers to achieve unmatched reliability, efficiency, and sustainability.

Prepared for the Future

The energy sector faces a critical challenge with aging pipeline infrastructure. Many pipelines, originally constructed decades ago, now require innovative solutions to remain safe, efficient, and sustainable. BrainDrip addresses this need with their composite pipeline system manufactured directly in the field. This process enables seamless pipeline rehabilitation, renewal, and greenfield installations tailored to meet modern energy demands and future requirements for hydrogen, CO2, and other renewable fuels.

Distributed energy storage is another cornerstone of the evolving energy landscape. As renewable energy generation grows, storage becomes a critical component for managing supply and demand. BrainDrip’s composite technology can be leveraged in the energy storage market and the system provides transformative solutions to address bottlenecks in natural gas, hydrogen, and CO2 storage. Manufactured on-site, the composite storage offers scalable, cost-effective storage that ensures energy reliability for day, week, and seasonal applications. These products help bridge the gap between today’s energy systems and the next generation of renewable fuels, positioning BrainDrip as a leader in the energy storage revolution.

Featured Products

Founded on multiple innovations in fiber composite reinforced polymers and a compact modular production platform, BrainDrip’s composite pipeline and storage products provide disruptive solutions to gas and liquids transmission, distribution, and large-scale storage applications. Our products provide solutions to long-standing problems in key industries and are future proof for changing markets.

Composite Pipeline

Transmission and distribution scale pipeline using BrainDrip’s composite product.

Pipeline rehabilitation, renewal, and greenfield installations

Pipeline rehabilitation, renewal, and greenfield installations

Wide range of pipe diameters, fluid compatibility, and pressure ratings

Wide range of pipe diameters, fluid compatibility, and pressure ratings

Continuous health and risk monitoring

Continuous health and risk monitoring

Composite Energy Storage

Large scale energy storage solution using BrainDrip's composite product.

High cyclability, high capacity, and high usable volume

High cyclability, high capacity, and high usable volume

Suitable for day, week, monthly, and seasonal storage applications

Suitable for day, week, monthly, and seasonal storage applications

Featured Services

BrainDrip’s expertise in product development, field manufacturing, and integrated system evaluations ensures a seamless customer experience. Our field manufacturing technology allows for rapid and precise manufacturing directly at project sites, minimizing costs and environmental disruption.

Additionally, our advanced health monitoring system provides continuous operational insights, ensuring the safety, reliability, and efficiency of your pipeline and storage assets. By integrating real-time monitoring with predictive analytics, we offer our customers peace of mind and proactive assurance that their energy infrastructure is secure and performing optimally.

With customized solutions for feasibility studies, commissioning, operation, and ongoing monitoring, BrainDrip supports our customers every step of the way.

Health Monitoring

BrainDrip’s Industry leading health monitoring system for pipeline and storage assets. Providing preventative external threat notification, product health, and performance integrated into your system or ours

FODT

The robotic Fiber Optic Deployment Tool (FODT), providing a unique fiber optic installation solution on the inner wall of a piping system. Enabling non-invasive fiber optic installation and monitoring in existing assets

Testing

Expertise and test facilities for full scale permeation of vessels and pipe systems up to 36” in diameter, burst testing and hydraulic pressure cycling, aging of materials, and custom testing services

Consulting

We provide expertise with a focus on hydrogen systems including technology acceleration, product commercialization, and safety and optimization assessment

Have a project for us?

Reach out to us to take the next step in getting your project off the ground!

Contact us