ITC-SV Product Advantages

Cost Effective Storage Capacities Starting at 1000 MCF Natural Gas and 2,000 kg H2: ITC-SV was developed to address the market gap for medium to large scale energy storage that can be installed in any geographic location. Our portable manufacturing platform enables individual ITC-SV segments to extend multiple miles in length, providing significant storage capacity while minimizing the number of joints and fittings. The on-site manufacturing method reduces costs by enabling shipment of bulk materials to the site rather than pre-fabricated short storage segments that must conform to DOT restrictions. ITC-SV’s storage capacities provide a superior alternative solution compared to the deployment of Type I-IV ground storage arrays, as ITC-SV can be direct buried, can be installed above ground without concrete pads or other support infrastructure, and provides superior storage capacity per unit land area. ITC-SV’s storage capacities also enable direct competition with liquid conversion and storage solutions such as liquid natural gas and liquid hydrogen, eliminating the energetic penalties of the liquefaction and regasification processes while providing storage capacities unattainable with more traditional gaseous storage vessels. In addition, BrainDrip’s Health and Risk Management System provides embedded and continuous high spatial resolution health monitoring of the ITC-SV asset, providing unparalleled operating confidence in the product over any other liquid or gas storage solution. There is no upper bound on the storage capacity of ITC-SV and additional capacity can be installed and integrated into the system as needed.

No geographical installation constraints: Unlike ground storage solutions such as depleted fields, salt caverns, and aquifers, ITC-PL does not require finding geologic structures and can be installed in any geographic location. In addition, because ITC-PL is an independently constructed composite structure with BrainDrip’s embedded HRMS, the risk of failure of the system is dramatically reduced in comparison to storage solutions that rely on the structure, stability, and containment of a geologic feature.

Multiple installation geometries for optimizing to land availability or cost: For locations where the land availability is high and/or the cost of land is low, ITC-PL can be installed as a single horizontal layer at the site in the desired geometry. For example, ITC-PL can be installed in the “pitchfork” configuration, where individual ITC segments multiple miles in length can be manufactured on-site and combined to form the storage network. When the amount of available land is limited and/or the cost of land is high, individual ITC-PL installation segments can be installed vertically into the ground in the “Silo” configuration. In the Silo configuration, existing foundation drilling rig technology is used to enable ITC segments to be installed hundreds of feet deep, providing a high storage density within a very small land footprint. For complex sites or those having unique requirements, hybrid installation of ITC-PL is possible, leveraging a combination of installation methods networked together through additional adjoining segments.

High Cyclability: Due to multiple innovations in BrainDrip’s core ITC and manufacturing technologies, the cyclability of ITC-PL is high compared to competitor storage solutions. With independent axial and radial reinforcement within the composite structure, innovations in the formation of the composite reinforcement structure, and dry fit construction without the need for crosslinking and bonding between layers, ITC-PL is highly resistant to cyclic fatigue and cracking which constrains the performance of competitor products. In addition, as ITC-PL’s storage capacity approaches that of geologic storage solutions, ITC-PL’s cyclability provides high throughput and low cushion gas requirements, outperforming the slow cycle limitations of geologic systems in many operating scenarios. Finally, BrainDrip’s integrated HRMS provides continuous validation of the ITC-SV product health in harsh cycling conditions through strain monitoring of the composite structure.

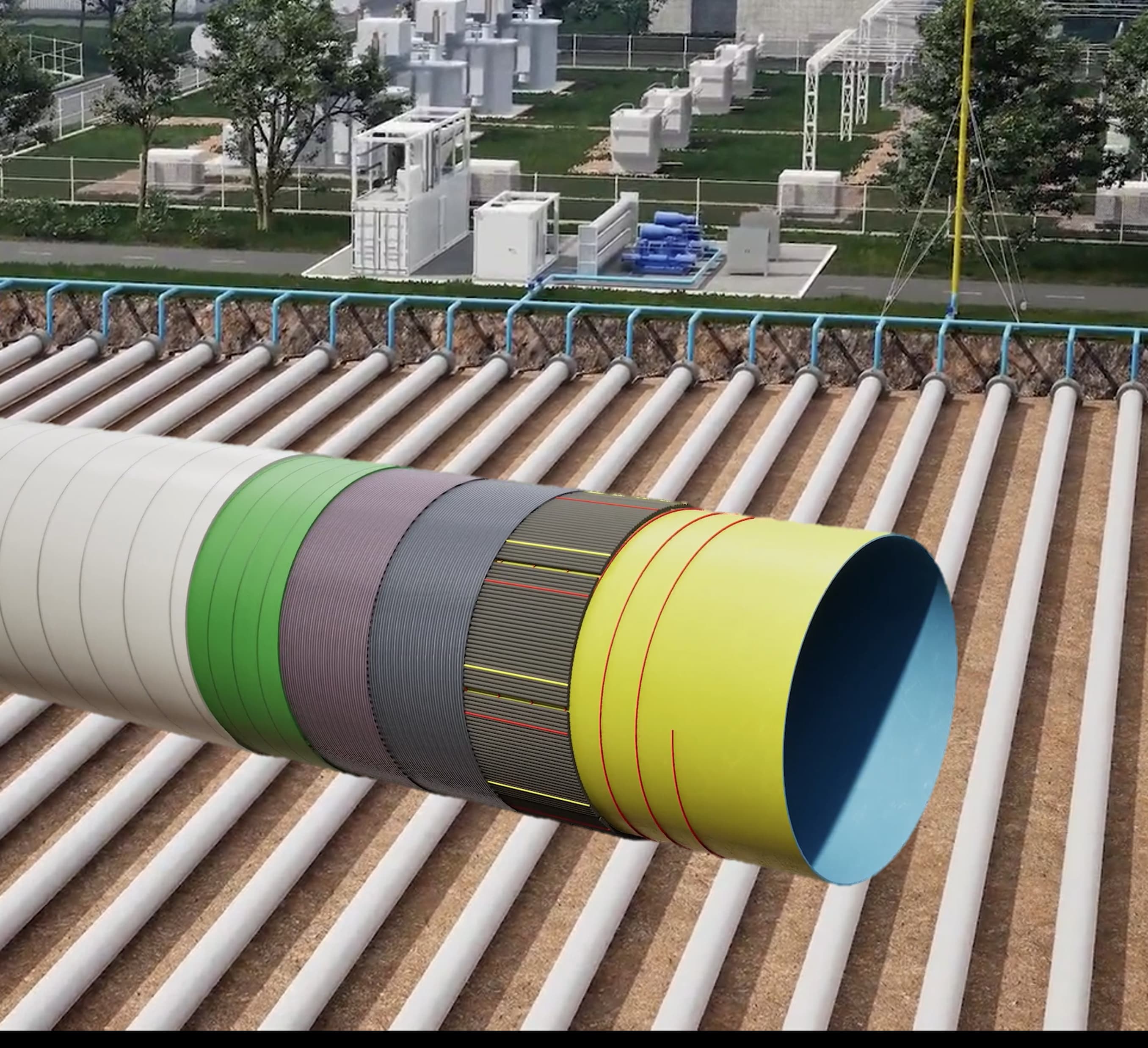

Storage Pressures up to 7500 psi: Storage pressure is a critical design element in the successful completion of an energy storage project, and in the determination of its cost. The customizability of the ITC-SV design and manufacturing enable tailoring the product to the exact requirements of a specific storage application. This customizability enables cost optimization for the application by designing to the exact storage capacity, pressure, and cycle requirements rather than picking a storage solution that is the “closest match”. In addition, for energy storage applications where multiple pressure levels are desired, multiple ITC-PL design variants can be installed and integrated with compression, expansion, thermal management, and other equipment. Through the independent application of axial and radial reinforcement layers within the product along with design variants in end couplers, ITC-SV can be manufactured for storage pressures up to 7500 psi, providing significant storage density and supply pressure when needed for downstream applications.

Compatibility with a wide range of gases and liquids, blends: ITC-SV is designed for compatibility with natural gas, hydrogen, carbon dioxide, water, NGL’s, gasoline and diesel fuel, methanol, and many other gases and liquids. With changing markets especially prevalent in the energy sector, installing a product designed for a gas or liquid today should also meet the needs of the markets in 2045. For this reason, the ITC-SV was designed to provide broad fluid compatibility. Our composite liner combines base polymer materials with novel coextrusions and materials to not only provide fluid compatibility, but also to mitigate the effects of permeation. The ITC-SV has been specifically designed to meet the challenging and unique requirements of hydrogen which includes natural gas/hydrogen blends, allowing for seamless future transition from natural gas to gas blends all the way to pure hydrogen.

Low maintenance costs: Due primarily to the ability of individual continuous ITC-SV segments to be manufactured on the scale of multiple miles, the number of valves, connections, and other fittings are significantly reduced compared to traditional ground storage solutions. For this reason, ITC-SV has very low maintenance costs compared to competitor products.

Embedded health and risk monitoring system: BrainDrip’s health and risk monitoring system is designed for and fully integrated into ITC-SV. This system combines distributed fiber optic sensing, traditional sensors, and advanced algorithms to detect third party threats such as encroachment, disruptions from events such as landslides, product health monitoring through composite strain measurement, leak detection, as well as performance metrics such as operating pressure, temperature, and flow conditions. ITC-SV is continuously monitored over the entire lifetime of the asset, providing you with unparalleled operational confidence. Click here for more information on BrainDrip’s HRMS (provide link to HRMS service).