11/27/24

Establishing a Goldilocks Zone for Distributed Electrolysis

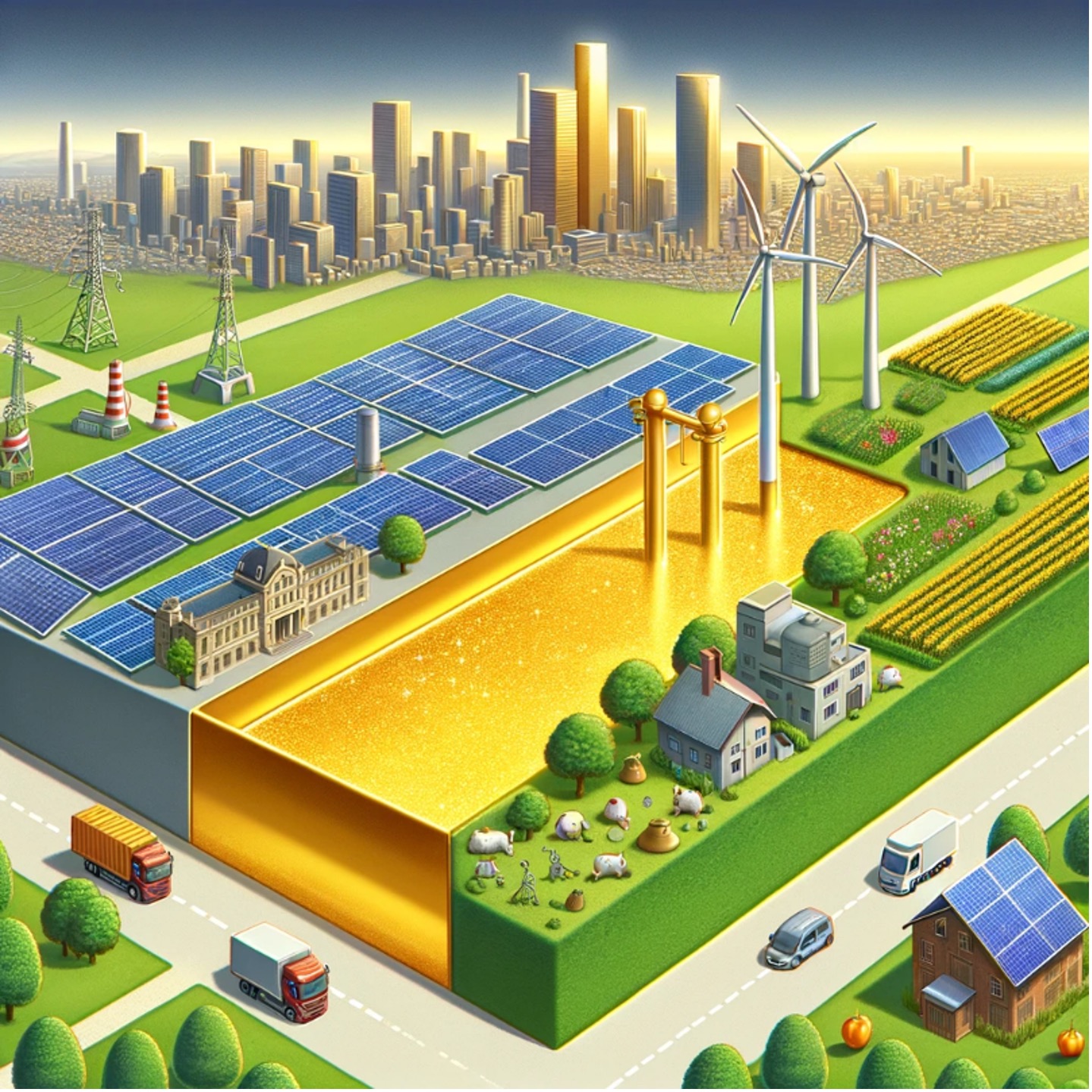

So, you are a hydrogen developer looking to produce renewable hydrogen from electrolysis in this emerging market? Great! Welcome to the industry – we have lots to discuss: storage, compression, off-take agreements, grid connection vs. islanding, lead times, costs, scaling the system over time, balance of plant, operations and maintenance, materials compatibility, siting and approvals, C&S, etc. but let's not get bogged down in those details yet. Let's just start with the basics - where are you going to put your systems?

Let's assume you are following a "distributed" production model and aren't an industrial gas company looking at something like centralized production with liquefaction or other pursuits like that. Maybe you are aiming for a couple of MW in size to several hundred MWs, or like, 1,000 kg/day – 100,000 kg/day.

You are the pioneers that are going to move this industry forward – truly, you are the risk takers that will demand innovation and make sure the economics work out. You were in this before DOE started handing out big dollars and you will be around after all that money has been spent on high-level executive meetings. We want to talk through this with you because we have experience in evaluating and installing these systems, and we need you to succeed. So, let’s talk about where you should physically put them and, when you get to the next level of design, give us a call.

Co-location with wind, solar, or other renewable electricity resources – it makes sense right? Your intention is to produce renewable hydrogen, you should be next to renewables. There are a couple of key benefits of doing this: 1) it will make it easier to demonstrate a path of electrons into your electrolyzer system – this is a requirement to participate in things like the Low Carbon Fuel Standard (LCFS) which started in California but is likely to be copied in other states (see ZEV growth for examples of how these standards are adopted over time) and 2) there are benefits to the grid using your electrolyzer as a balancing load near variable resources like wind and solar. Your utility will thank you for that – maybe they should pay you for it too? Side note: the second bullet has been demonstrated extensively by NREL, but I am too busy to provide a link for y’all because this isn’t a formal report – I got out of that game for a reason. Just search “Kurtz Renewable Electrolysis” or “Eichman Renewable Electrolysis” and it will take you to a few reports that highlight those extremely useful results.

You need POWER – don’t catch an extra capital cost item by needing to upgrade a substation near your site. If you can, select a site that already has significant power available. Yes, even if you don’t intend to produce hydrogen from the grid, there may be site requirements around how much power you can pull from the grid and you still have all that balance of plant, right? Electrolyzer systems don’t get more efficient the longer you operate them, in fact they do the opposite.

Who are you selling to? You must be close to the end-user – ideally you are within 100 miles of any end-user and aim for being within 200 miles from your furthest end-use partner if you have multiple. That way you can justify the use of tube trailers until hydrogen pipelines become more common. Maybe you can aim to be close to a city center, port, industrial center, airport, etc.

Cheap (ish) land – this is just a CapEx thing. So, you need to be close to a city center but, you know, not that close. Also, will need more land than you think – the electrolyzer and balance of plant around that system is one thing but you will also need significant buffer storage to handle variations in timing of tube trailers arriving and filling, also you need some capacity if your electrolyzers need to go down for maintenance (spoiler alert: they will! Quite a bit at first, but you will get better at keeping them online). Speaking of long-duration storage, we have that in our portfolio – give us a call when you need some installed.

You need access to water – If your system was perfect at water management, you are still going to be using 2.4 gal of water for every kilogram of hydrogen you produce. Unfortunately, real systems use more than this, sometimes quite a bit more. If you are in an area where you have sediment in your water – you may need a RO system in which case, you are rejecting a lot of water as well. So, you need to find a spot that may have other uses for grey water as well.

There are probably plenty of other aspects we are missing but this is a good start. Let’s recap. You want to be near or within a city center due to your requirements for power and the need to be close to an end-user. You also want to be far outside a city center so you can get cheap land, co-locate with a lot of renewables, and have space for your site energy storage. You also kinda want to be on the outskirts of a city center so you can be near industrial processes. You want to be next to a water supply that you can use, and no one will care. Oh, and you also want to be next to a farm, nature preserve, or golf course that can use your grey water… Simple, right? Good luck out there, Pioneer – you’ve got this!

As always – stick around, things could get interesting.

Credit: The article image was created with the use of A.I., specifically OpenAI’s DALL-E platform. Main author is Mike Peters with proof reading and editing provided by the broader IQ4H2 team.